Phillip Smith

Vice President, Manager, Building Materials

Phone Number:

+1 (1)781 255 4783

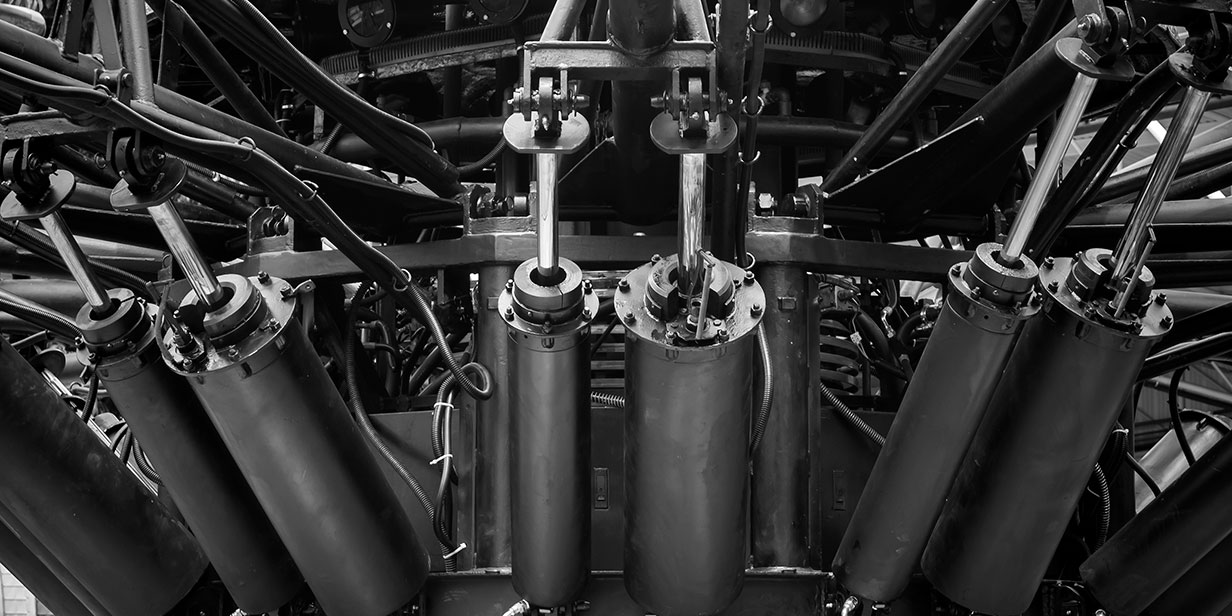

Pressurized industrial fluids such as turbine lubricating and control oils or hydraulic fluids present a considerable fire hazard. These fluids are typically conveyed through metal piping with welded, flanged or threaded joints at pressures up to several thou- sand pounds per square inch.

Fluid released under high pressure typically results in an atomized spray or mist that can easily ignite when it contacts hot surfaces, open flame or an electrical arc. The resulting fire is torch-like and very difficult to control, even with automatic sprinkler protection. A spray fire can extend up to 40 ft. (12.2 m) from the release point and can easily ignite combustibles and severely damage steel building elements or metal equipment.

FM loss statistics indicate failures involving lubrication and hydraulic control systems within power generation facilities, for example, have resulted in numerous spray, pool and three-dimensional fires.

There are many ways to help reduce the risk of spray fires and other types of fire related to ignitable fluids. Properly designed hydraulic equipment, for instance, will shut down quickly, preventing the release of additional fluid into a fire. In facilities where hydraulic equipment is designed with automatic shutoffs, the provision of a basic sprinkler system will provide adequate protection for most expected fire scenarios.

However, in cases where hydraulic systems may not shut down quickly--as in the case of many power generation turbines that need continuous lubrication during shutdown to avoid catastrophic damage--automatic sprinkler discharge can help limit damage to the building structure, but the spray fire will not be extinguished until the oil supply is shut off.

One way to help reduce risk is to use FM Approved industrial fluid, which represents a low fire hazard and does not require additional automatic sprinkler protection. In addition, spray fire risk can be further reduced by installing FM Approved spray fire shields on mechanical pipe joints.

Spray fire shields are installed around pipe flanges and fittings to protect workers from hazardous leaks and sprays, to help indicate leaking joints and reduce the risk of fire or explosion from leaking ignitable fluids. Spray fire shields may be required to meet regulatory standards set by governmental and industrial agencies and organizations. Shields are just one element in a fire protection strategy that should include:

Spray fire shields are made from a wide range of materials to suit the intended application, including Teflon®, polypropylene, polyvinyl chloride, polyethylene, and stainless or galvanized steel.

FM Approved spray fire shields are evaluated according to Approval Standard 4999, Spray Fire Shields. The standard includes leak tests with piping in horizontal and vertical positions, as well as a fire integrity test in which the sample shield is subjected to fire exposure for 45 minutes and immediately followed by a leak test.

The intent of this test protocol is to simulate a high pressure leak at a pipe joint, and the ability of the spray fire shield to control the resulting spray and limit any fire to a more manageable pool fire. The performance tests evaluate the product’s ability to withstand a pool fire until the fluid flow can be shut off or the fire controlled or extinguished.

To date, all FM Approved spray fire shields are made of stainless steel as no fabric spray shields have been able to pass the 45-minute fire test.

FM Approvals is the only Nationally Recognized Testing Laboratory (NRTL) that currently tests and certifies spray fire shields. All FM Approved spray fire shields have undergone extensive testing that assures the highest level of performance in real-world conditions. These shields can limit the extent of damages and downtime related to high-pressure leaks of hydraulic, lubricating, and other ignitable fluids.

By fitting FM Approved spray fire shields over oil piping flanges, the spray fire hazard at the flange can be reduced to a localized spill and pool fire that can be controlled by local automatic sprinkler protection, curbing and emergency drainage for the area of the release. FM Approved spray fire shields are subjected to a 45-minute hydrocarbon fire, during which they have demonstrated the ability to maintain their structural integrity and limit the release of oil to within a 5 ft (1.5 m) radius from the centerline of the shield.

The FM Approvals certification program is an investment that demonstrates a manufacturer’s confidence in its products. While FM Approval’s testing is considered among the most rigorous in the world, it is also a true sign of a manufacturer’s confidence and a quality indicator that will help differentiate a product from its competition.

FM Approvals partners with its customers, providing insights that can strengthen product design with ongoing support. FM Approved products are not only listed in the Approval Guide but, just as importantly, FM Approved products are specified and accepted by building owners, designers and code authorities, and regularly recommended to FM clients in nearly 200 countries by 1,800 FM engineers.

Conformance to the following standards verifies that spray fire shields meet the stated safety and performance criteria, providing assurance in their ability to protect against fires resulting from high pressure leaks.

FM 4999

Spray Fire Shields

FM 6930

Fire Performance of Industrial Fluids

FM 6933

Transformer Fluids

Begin the approval application process